FutureGrid

The transition from natural gas to hydrogen is an important technical priority for National Gas – and is critical to the delivery of net zero for the UK. FutureGrid is providing vital insights into hydrogen transportation and blending – to support the full-scale conversion to hydrogen.

Leading the way in the transition to hydrogen

As the UK prepares for the transition to hydrogen, it’s vital to demonstrate that the National Transmission System (NTS) and existing gas pipelines and assets can operate safely with hydrogen.

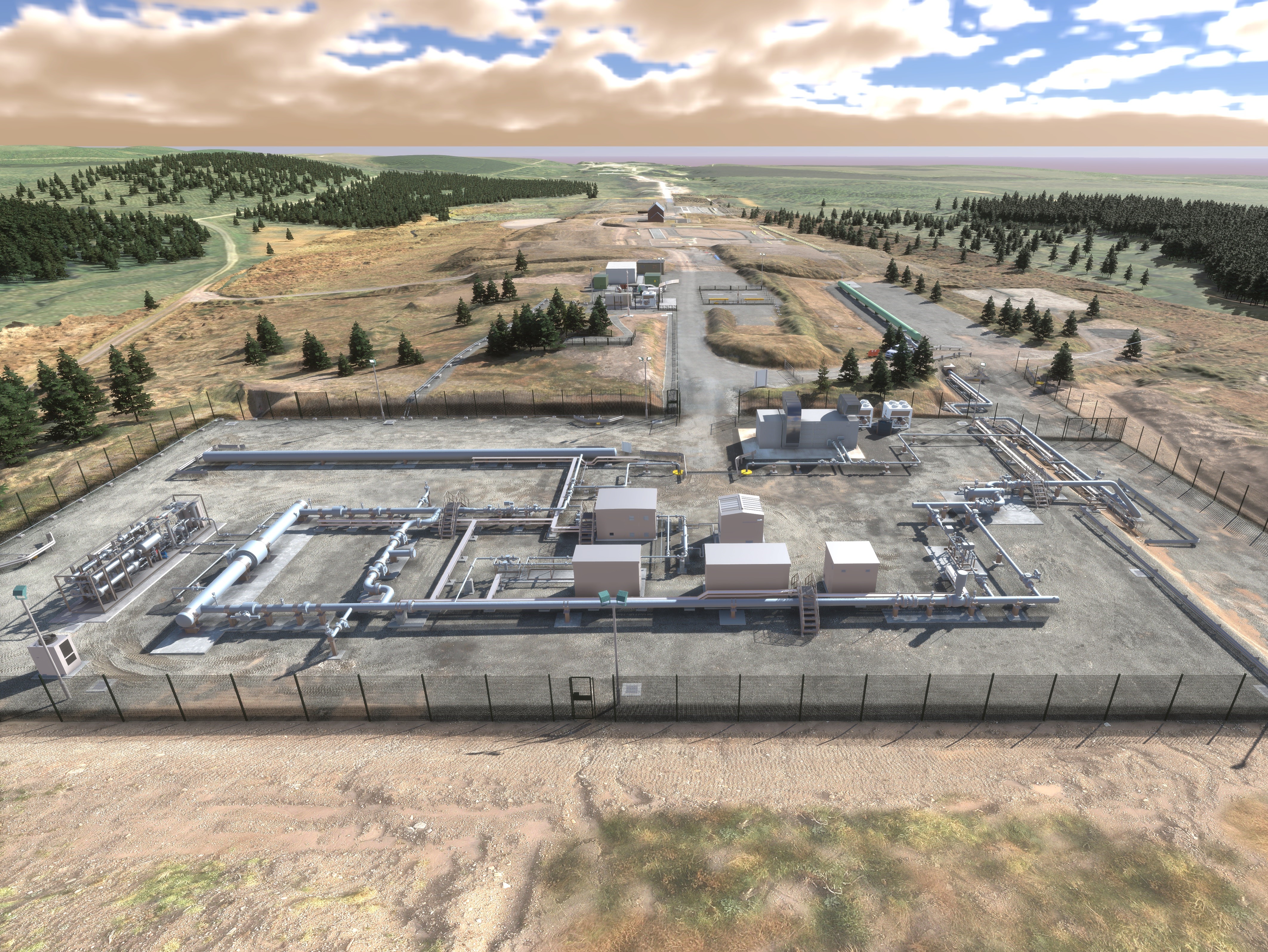

That’s why we have created the FutureGrid high-pressure test facility at DNV Spadeadam to carry out a wide range of essential hydrogen tests. Purpose-built using recently decommissioned NTS assets, this micro-transmission network allows us to carry out extensive tests in a secure offline environment, replicating every part of the gas transmission system. These tests will enable us to assess the effects of hydrogen on our pipes and assets, and on the operation of the network.

The aim of FutureGrid is to develop processes and safety standards that will allow us to run a safe and reliable national hydrogen transmission network. The outcomes of FutureGrid will inform the development and design of Project Union.

FutureGrid Phase One

Demonstrating Hydrogen Readiness Across the UK Gas Network

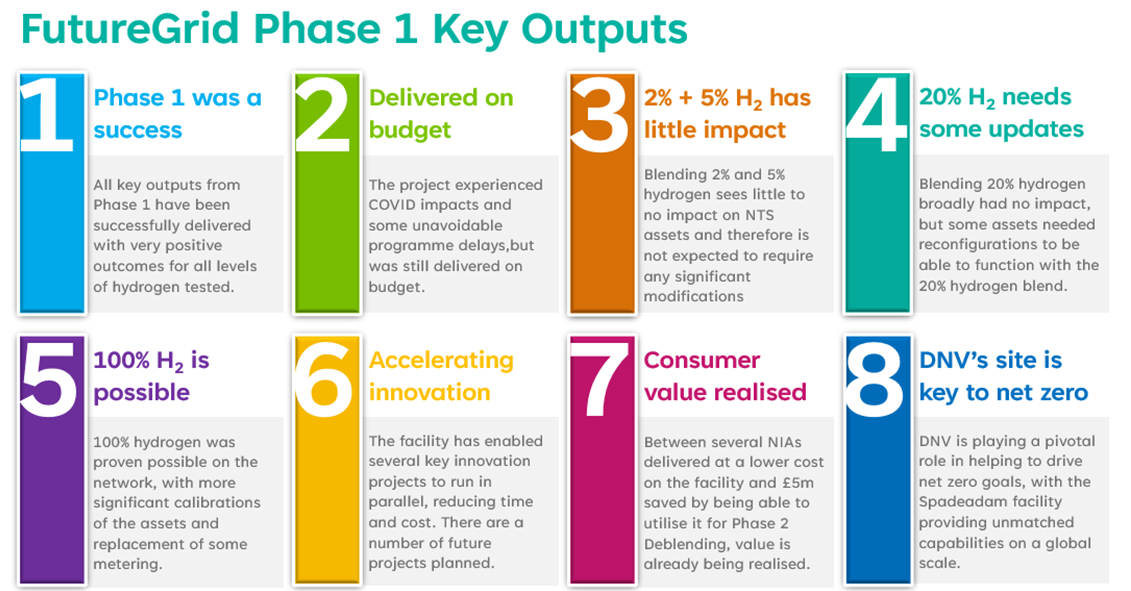

FutureGrid Phase 1 was a landmark innovation project led by National Gas, designed to test whether existing National Transmission System (NTS) assets could safely and reliably transport hydrogen. As part of the HyNTS programme, this project laid the technical foundation for transitioning the UK’s gas infrastructure to support blended and 100% hydrogen.

The project aimed to construct a world-first hydrogen test facility utilising decommissioned NTS assets to conduct flow testing with 100% natural gas, 2%, 5%, and 20% hydrogen blends and 100% hydrogen alongside standalone leak testing, flange integrity, material permeation and fatigue and rupture testing. The outputs were utilised to develop a comprehensive Quantitative Risk Assessment (QRA) and updated safety case documentation.

The FutureGrid Phase 1 project demonstrated that hydrogen blends up to 20% and even 100% hydrogen can be safely transported using existing infrastructure, with validated safety systems and fatigue-tested materials ensuring reliability. Leak and flange tests confirmed gas-tight integrity, while updated procedures addressed hydrogen-specific risks. The facility has become a global benchmark, hosting over 1,000 stakeholders and supporting the UK’s hydrogen backbone strategy through Project Union and Phase 2 initiatives.

Document Library

Progress reports

Closure reports

FutureGrid Phase 1 Closure Report 2024

Testing Guide

FutureGrid Deblending

Unlocking Hydrogen for Transport Through Innovation

The FutureGrid Deblending for Transport project, funded by OFGEM’s Strategic Innovation Fund (SIF), is a pioneering initiative led by National Gas to demonstrate how the UK’s existing gas infrastructure can be repurposed to deliver pipeline-fed hydrogen for transport and mobile power applications.

This project is a critical step in enabling zero-emission transport by showcasing how hydrogen can be separated, purified, and compressed for use in fuel cell vehicles and other clean energy systems.

Why Deblending Matters

Hydrogen blending into the National Transmission System (NTS) offers a scalable route to decarbonisation. However, many transport applications require high-purity hydrogen. Deblending technology allows hydrogen to be separated from natural gas blends and purified to fuel-cell grade, enabling reliable supply for refuelling stations and mobile power.

Without deblending, hydrogen refuelling stations are limited to local production or tube trailers, which often leads to supply constraints. This project aims to solve that by demonstrating a pipeline-connected hydrogen refuelling solution whilst also working with stakeholders across the full supply chain to produce a rollout and commercialisation strategy to understand the future potential of this demonstration.

Document Library

FutureGrid Deblending Progress Report 2025

FutureGrid Deblending Progress Report 2024

CENEX - Hydrogen Transport Rollout Strategy

ERM - Hydrogen Transport Rollout Strategy

FutureGrid Carbon

Enabling the CCUS value chain through the efficient transportation of Carbon Dioxide

FutureGrid: CO2 is a project funded by OFGEM’s Strategic Innovation Fund (SIF) and is addressing key technical challenges associated with transporting carbon dioxide within the gaseous phase. This includes carbon dioxide venting dispersion validation, testing gas analysers and corrosion rates of typical off-spec situations, large dispersion validation through rupture tests and finally observing how carbon dioxide behaves when transported in repurposed pipelines and assets.

This project holds the answers to important technical questions and will enable the continuation of Carbon Capture, Utilisation and Storage (CCUS) projects across the world, such as SCO2t Connect, in order reach the overall goal of Net Zero by 2050 and the decarbonisation of hard-to-abate sectors.

Why CCUS matters

The UK’s Climate Change Committee (CCC) stated that CCUS is a ‘necessity and not an option’ to achieve climate change targets. In addition to this the International Energy Agency (IEA) has further clarified that ‘Reaching net-zero by 2050 will be virtually impossible without the significant deployment of CCUS technology’. These strong statements have been made because CCUS is the only viable way for some hard-to-abate sectors to decarbonise and it’s a crucial path to Clean Power and hydrogen production. For the UK in particular, CCUS paves the way for decoupling economic growth with emissions, enabling us to keep industry and jobs without failing to hit our legally-binding environmental targets (Paris Agreement and Net Zero).

FutureGrid Compression

HyNTS FutureGrid Compression was a Strategic Innovation Fund–supported project within National Gas’s FutureGrid programme.

The purpose of the project was to explore whether existing National Transmission System compression assets could be repurposed for hydrogen blends & 100% hydrogen. Initial findings suggested that gas turbines could be modified to operate on up to 100% hydrogen, and that existing compressors may function with blends of up to 50% hydrogen - we concluded that upgrades are required beyond this threshold.

The project’s Beta phase aimed to validate these assumptions through technical trials & testing delivered by DNV at RAF Spadeadam, building on Phase 1 findings, with Siemens Energy engaged to deliver the required modifications.

Following a joint review with UKRI and Ofgem, the project closed in 2025, with its insights now informing Project Union, hydrogen blending, and future hydrogen infrastructure planning across Great Britain.

Partner with FutureGrid

Explore Commercial Opportunities with the UK’s Leading Hydrogen Demonstration Facility

FutureGrid is more than a demonstration site — it’s a launchpad for innovation. As part of our commitment to accelerating the hydrogen economy, we’re now open to commercial partnerships and enquiries.

Whether you're a technology developer, equipment manufacturer, academics or any part of the hydrogen supply chain, FutureGrid offers a unique opportunity to:

- Test and validate hydrogen technologies at transmission scale

- Demonstrate hydrogen refuelling solutions in real-world conditions

- Access valuable operational data to support product development

- Collaborate with National Gas and industry leaders shaping the future of energy

We welcome enquiries from organisations interested in:

- Commercial demonstrations

- Equipment testing

- Strategic partnerships

- Data access and collaboration

Get in Touch

To discuss opportunities or request more information, please contact us at: [email protected]